ANSI Standard Limits and Fits (ANSI B4.1-1967,R1974) ANSI, This American Standard for preferred limits and fits for cylindrical parts presents definitions of terms applying to fits between nonthreaded cylindrical and makes some recommendations on preferred sizes, fits, tolerances, and allowances for use where they are applicable. The ANSI B4.1 charts data are provided in thousandths (.001) of an inch. ANSI can be defined ANSI metric or ANSI Inch system.

ANSI decimal inch system is based on ANSI Standard (B4.1 - 1967(1979). ANSI Standard (B4.2 - 1978)metric system is based on ISO millimeter system. ANSI - American National Standards Institute. ISO is International Organization for Standardization.

Tecnotest Reflex Keygen Software. Fits and Clearances Pocket Guide Fits between Radial Bearings and Housing Bores. Fits and Clearances Pocket Guide Tolerances for Shaft Diameters 3 6 0 – 30.

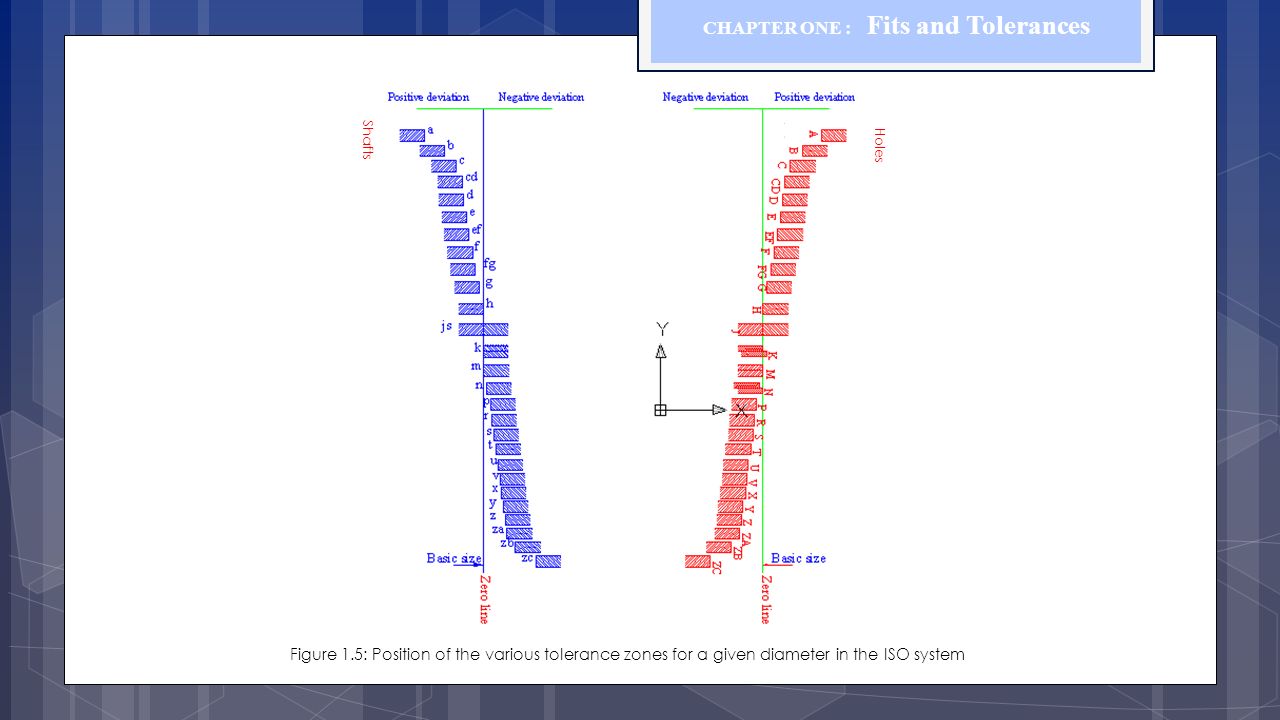

ANSI standard is in accord with the recommendations of American-British-Canadian (ABC) conferences up to diameter of 20 inches.The ABC proposal comprises:(a)A grade system of fundamental tolerances for diameters 0.04 inch to approximately 20 inches, the tolerance values in each grade being to the diameter by a given law of formula and each grade of tolerance being approximately related to the others in the system in a preferred number ratio (R5 series, with 60 percent increments). (a) A series of unilateral hole limits derived from the fundamental tolerances, for use with a hole basis system. (c) A series of shaft, one of these limits being determined by the allowance ( according to some technical requirement), the other being derived from it by addition or subtraction of the fundamental tolerance.(d) A selection of fits made by recommended association of certain of the holes and shaft, the selection being adequate to cover most engineering requirements. Bharateeyudu Songs Download Southmp3. What can be effective for selection of the fits? Many factor can be affective for selecting proper fits such as bearing loads, speed, materials, length of engagement, lubrication, humidity, and temperature etc.

This all affect must be taken into consideration in the selection of the fits for proper applications. ANSI B4.1 - 1967(1979), R1974 Standard Tolerances ANSI B4.1 standard implements 10 tolerance grades to meet the requirements of various production branches for accuracy of products. ANSI B4.1 standard defines a system of preferred fits only for basic sizes up to 19.69 inch.

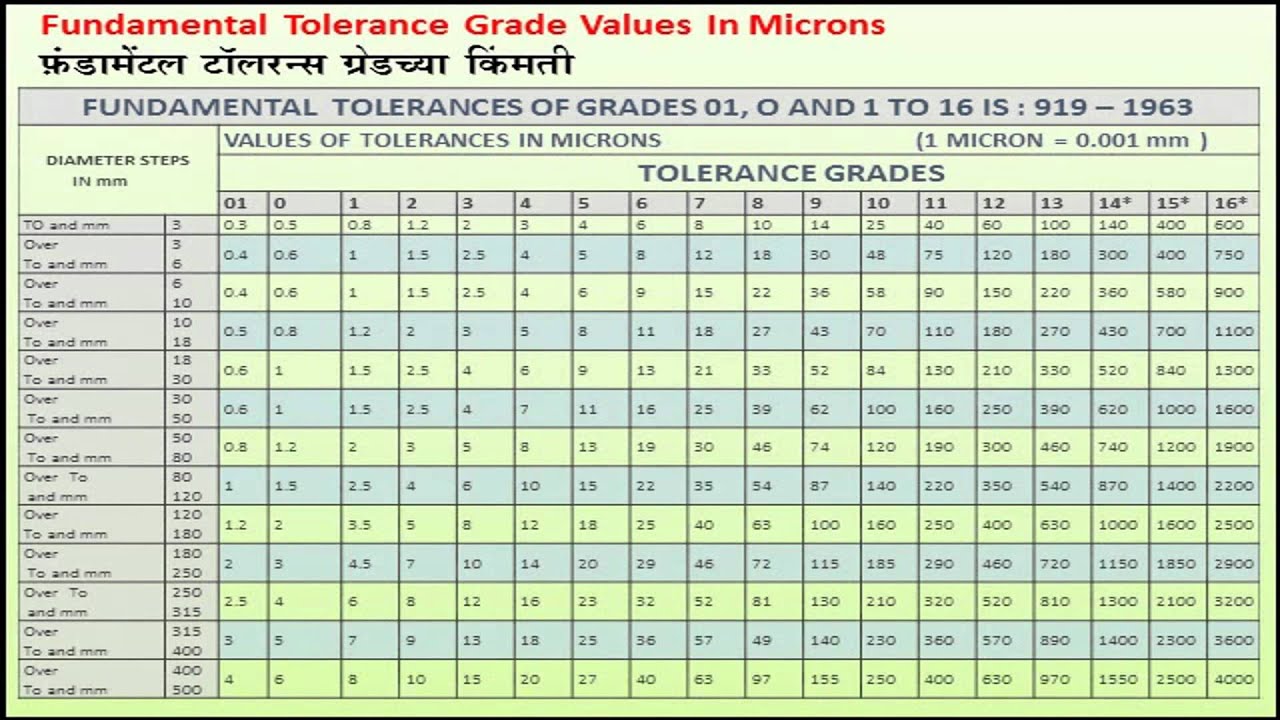

ANSI B4.1 system of tolerances is prescribed by the standard for basic sizes up to 200 in. ANSI B4.1 Tolerance Table provides a suitable range from which appropriate tolerance for holes and shaft can be selected. This enables the use of standard gages. Table shown below. NOMINAL( BASIC) SIZES (INCHES) INTERNATIONAL TOLERANCE GRADES OVER UP TO INCL.